A Synthetic Fiber Used In Manufacturing Carpet

Synthetic fibers are commonly used in the production of carpets due to their low cost and durability. The most common synthetic fibers used in carpet manufacturing include nylon, polyester, olefin, and acrylic. These synthetic fibers provide a range of benefits, such as being colorfast, stain-resistant, and resistant to fading. Synthetic fibers are also easier to clean than natural fibers, making them an ideal choice for high-traffic areas. Additionally, synthetic fibers are more resistant to mold and mildew, which is beneficial in areas with high humidity. While synthetic fibers offer many advantages, they are not as soft or luxurious as natural fibers like wool.

What is Synthetic Fiber?

Synthetic fiber, also known as man-made fiber, is a type of material that is produced from synthetic materials such as polypropylene, nylon, acrylic, and polyester. These materials are derived from petrochemicals and are used to produce a variety of fabrics, including carpets. Synthetic fibers are strong, lightweight, and resistant to water and stain damage. They also offer a range of other benefits, including enhanced durability, improved color retention, and a softer feel. Synthetic fibers are also more affordable than natural fibers, making them an ideal choice for manufacturing carpets and other fabrics. Manufacturers can use synthetic fibers to create carpets with a variety of colors, textures, and styles, allowing them to create carpets that are both beautiful and functional. Synthetic fibers are also highly resistant to fading, making them a great choice for carpets that will stand the test of time.

Advantages of Synthetic Fiber in Carpet Manufacturing

Carpet manufacturing has seen a huge shift in recent years due to the introduction of synthetic fibers. Synthetic fibers are derived from man-made materials such as nylon, polyester, and polypropylene, and they provide manufacturers with a wide range of benefits when used in carpet production. From improved durability to cost savings, synthetic fibers in carpet manufacturing have revolutionized the industry.

For starters, synthetic fibers are highly durable and resistant to wear and tear. This makes them the ideal choice for carpets that are used in high-traffic areas such as entranceways and common areas. Additionally, synthetic fibers are available in a variety of colors and textures, which makes them ideal for customizing products with unique designs and patterns.

Another advantage of synthetic fibers in carpet manufacturing is the cost savings they provide. Synthetic fibers are typically less expensive than natural fibers, which can reduce the overall cost of production. Additionally, synthetic fibers are easier to produce and use less energy in the manufacturing process, which can also help to reduce costs.

Finally, synthetic fibers are more environmentally friendly than natural fibers. They are non-toxic and biodegradable, which makes them a better choice for the environment. Additionally, synthetic fibers typically generate fewer emissions during the production process, which makes them a more sustainable option.

Overall, synthetic fibers offer a wide range of advantages for carpet manufacturers. From improved durability and cost savings to increased sustainability, synthetic fibers have revolutionized the industry and are quickly becoming the preferred choice for carpet producers.

Types of Synthetic Fibers Used in Carpet Manufacturing

Carpeting is one of the most widely used flooring materials in the world. It is available in a variety of colors, textures, and styles, and can be made from a variety of materials. One of the most popular materials used in carpet manufacturing is synthetic fibers. There are several different types of synthetic fibers used in carpet production, each of which has its own unique characteristics and benefits.

Nylon is one of the most common synthetic fibers used in carpet manufacturing. It is a strong and durable fiber that is resistant to staining, fading, and wear. Nylon carpet is also relatively easy to clean and maintain. Polyester is another popular synthetic fiber used in carpeting. It is resistant to stains and mildew and is also very affordable. It is also resistant to crushing and offers a softer feel than nylon.

Acrylic is another type of synthetic fiber used in carpet production. It is highly resistant to fading, staining, and wear, and is also resistant to mildew and mold. Acrylic carpet is also relatively easy to clean and maintain. Olefin is another synthetic fiber often used in carpet manufacturing. It is highly resistant to staining, fading, and wear, and also offers good colorfastness and low moisture retention.

Each type of synthetic fiber used in carpet production offers unique characteristics and benefits. It is important to consider each of these when selecting the right material for your carpeting project. By understanding the various types of synthetic fibers used in carpet production, you can find the best option for your needs.

Production Process of Synthetic Fiber Carpets

Synthetic fiber carpets are a popular choice for many homeowners due to their low maintenance and durability. Thanks to advances in technology, these carpets can now be produced with a range of different synthetic fibers, such as nylon, polyester, and olefin, each of which offers unique benefits. But how exactly is synthetic fiber carpet produced?

The production process for synthetic fiber carpets begins with the spinning of the fiber into yarn. This yarn is then tufted or woven onto a backing material, usually a jute or cotton backing. A latex adhesive is then applied to the backing material to hold the yarn in place. This is followed by a process known as “heat setting” in which the yarn is heated to a high temperature in order to set the fibers in place. Finally, a secondary backing material is added to the underside of the carpet to give it extra strength and durability.

Synthetic fiber carpets can also be treated with a variety of finishes to provide additional benefits. These include stain protection, soil resistance, anti-static treatments, and flame retardants. This makes them ideal for high-traffic areas and homes with young children or pets.

Synthetic fiber carpets offer a more affordable alternative to natural fiber carpets while still offering the same look and feel. Thanks to the advances in production technology, synthetic fiber carpets are now more durable and easier to care for than ever before.

Quality Control and Testing of Synthetic Fiber Carpets

Synthetic fiber carpets are becoming increasingly popular in the home furnishing industry due to their durability and affordability. These carpets are often made with a combination of different synthetic fibers, such as nylon, polyester, and olefin, and must undergo rigorous quality control and testing in order to meet industry standards. Quality control testing is designed to ensure that the materials used in the carpets are up to par and meet all safety and performance requirements. It also ensures that the carpets are free from any defects or irregularities. Testing is conducted at multiple stages during the manufacturing process to guarantee the highest quality product is delivered to the end consumer.

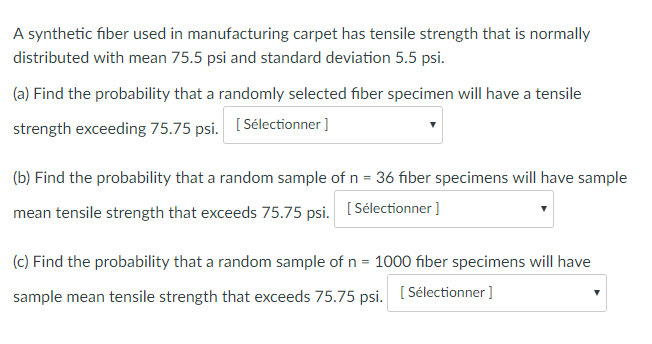

During the quality control testing, the fibers are tested for strength, colorfastness, pilling, abrasion resistance, tensile strength, and dimensional stability. The carpets are then inspected for any visible defects or flaws. Tests are also conducted to check the carpet’s resistance to stains and fading. These tests are conducted in order to ensure that the carpets are of the highest quality and will be able to withstand heavy traffic and wear and tear. Quality control testing is essential to ensuring that the carpets manufactured are safe, durable, and of the highest quality.

Innovations in Synthetic Fiber Carpet Manufacturing

Synthetic fibers are increasingly being used in the manufacture of carpets, leading to a new generation of resilient and stylish flooring options. From durable polypropylene and nylon to luxurious triexta and olefin, synthetic fibers are revolutionizing the carpet industry. These new fibers offer a range of benefits including enhanced stain resistance, improved durability, and increased softness and comfort. Manufacturers are taking advantage of synthetic fiber technology to create carpets that are more stylish, maintain their appearance better over time, and provide superior performance. In this article, we’ll explore the advantages of synthetic fiber carpeting and the innovations that are driving the industry forward.

Synthetic fibers are particularly suited to carpeting due to their strength, resilience, and low cost. Polypropylene is a popular choice due to its high resistance to stains and fading, while nylon is known for its superior softness and comfort. Triexta and olefin are newer fibers that offer superior stain resistance and a luxurious feel. These new fibers are increasingly popular for commercial and residential applications and are becoming a go-to choice for carpet manufacturers.

In addition to these traditional synthetic fibers, manufacturers are now utilizing advanced technologies to create carpets with enhanced performance and style. These innovations include high-performance yarns that provide superior resilience, ultra-soft fibers that provide luxurious comfort and engineered surfaces that improve stain and water resistance. By leveraging the latest fiber technologies, manufacturers are creating carpets that are more resilient, stylish, and comfortable than ever before.

Synthetic fibers have revolutionized the carpet industry, leading to a new generation of stylish and durable flooring options. From polypropylene and nylon to triexta and olefin, synthetic fibers offer a range of advantages that make them ideal for carpeting. Manufacturers are now leveraging advanced technologies to create carpets with enhanced performance and style, making them a go-to choice for both residential and commercial applications.

Challenges Faced in Synthetic Fiber Carpet Manufacturing

Synthetic fiber carpets are a popular choice due to their durability and affordability. However, manufacturing such products is not without its challenges. Synthetic fiber carpets are made from man-made fibers, such as nylon, polyester, and olefin. These fibers are derived from petroleum, so the process of producing them is often energy-intensive and expensive. Additionally, the fibers can be damaged in the manufacturing process if not handled properly, resulting in a lower-quality product.

The way a synthetic fiber carpet is constructed can also be a challenge. Although they are often made with a tufting machine, the complexity of the designs and the amount of work required to create them can be time-consuming and difficult. Additionally, the use of dyes and chemicals to create the desired color can be damaging to the environment, leading to concerns about sustainability.

Finally, synthetic fiber carpets require specialized care for proper maintenance. They are often treated with stain-resistant chemicals, which can be difficult to remove and can leave a residue on the fibers. This can make them difficult to clean and can lead to long-term damage if not addressed properly.

Overall, there are several challenges associated with manufacturing synthetic fiber carpets. From the energy-intensive production process to the complexity of the designs to the specialized care they require, these challenges can make the process of producing them difficult and costly.

Conclusion

Synthetic fibers have become an important part of the manufacturing process for carpets, providing a durable, long-lasting floor covering that can stand up to the rigors of everyday use. The ability to customize the fibers used in manufacturing carpets has allowed for a wide variety of colors, textures, and patterns, making it easier to find the perfect carpet to fit any decor. With the vast array of synthetic fibers available, manufacturers are able to create carpets that are both aesthetically pleasing and durable enough to stand up to everyday wear.